Innovative digital technologies have a crucial role to play in the pathways toward decarbonisation in building and construction. Across the entire supply chain, from manufacturers to designers and builders, digital technologies are used to help reduce the carbon associated with the manufacture of materials and construction of buildings and infrastructure – also known as embodied carbon.

The Materials & Embodied Carbon Leaders’ Alliance (MECLA) brings together the drive to reduce embodied carbon in the building and construction industry. The built environment makes up 40% of annual global CO2 emissions. MECLA is determined to transform the building and construction sector to reach Net-Zero emissions through our systems interventions. Part of this transformation includes the development of several Spotlights and articles to support knowledge sharing with industry.

On 31 March 2023 MECLA’s Spotlight on Digital Technologies for Lowering Embodied Carbon featured a diversity of speakers including suppliers, designers and engineers speaking about the different technologies used to achieve lower carbon outcomes. The presentations covered technologies in both the commercial and residential sectors, demonstrations on diverse ways digital twins are being used, how digital modelling helps inform design decisions, and what tools engineers are using to track the embodied carbon of projects.

Digital Twins and Embodied Carbon

Digital twin technology creates a model replica of a real-life asset. This technology can be used to deliver lower carbon outcomes in process manufacturing and design/build decision making.

“Digital Twin is a natural place for carbon to sit in terms of making intelligent decisions and pooling as much data as possible.” Scott Selkirk, Director Extended Reality at Mott MacDonald said in an interview about their recently launched Carbon Twin tool.

The Carbon Twin is an interactive platform built on the Unity gaming engine that visualises the carbon embedded in infrastructure projects. It provides an easy and interactive game like experience for designers and decision makers to explore where the carbon hot spots of projects are, driving design changes to reduce carbon.

Carbon Twin displays breakdowns on different materials, the carbon emissions associated with those different materials, and the carbon costs. It allows users to navigate across an asset and gain visibility into the emissions associated with each part of the portfolio.

“For regulators and investors, it has been previously very difficult to identify and understand where the carbon intensity is in the infrastructure. With the Carbon Twin you can highlight where that carbon intensity is in a visual way across the entire portfolio, what that means is those decision makers can be asking for changes in the design.” Explains Andrea Gaffney, Net Zero Lead at Mott MacDonald.

Crucially, Carbon Twin makes the complex world of carbon easy to understand for everyone involved. In other words, it democratises carbon. As Andrea explains, “Carbon and sustainability are typically the province of the climate change teams and the carbon specialists. But as we move toward a net zero future, and are required to clean up our operations and green our activities, then we need new ways, new tools, new innovations that are going to enable other people in the infrastructure ecosystem to understand carbon and to help them on the net zero journey.”

Digital twins have also been implemented by material manufacturers to manage their carbon emissions and achieve reductions. BlueScope Steel has recently created a digital twin of the Port Kembla Steelworks. Kembla is an integrated steelworks that takes virgin iron ore, coal, and other raw materials and produces steel slabs, hot rolled coil and plate. The steelworks are a very complicated a large operation, very capital intensive and a long-lived asset. Making any changes to process a potential major ramification and extended impact.

Historically, BlueScope had a very complicated excel model using annual averages to help them understand what a change could mean. But with their digital twin and graphic interface, Iain McDonald, Carbon Abatement Manager at BlueScope, is able to modify a hundred different parameters to see the effect on steel-carbon intensity.

Residential Carbon Tracking

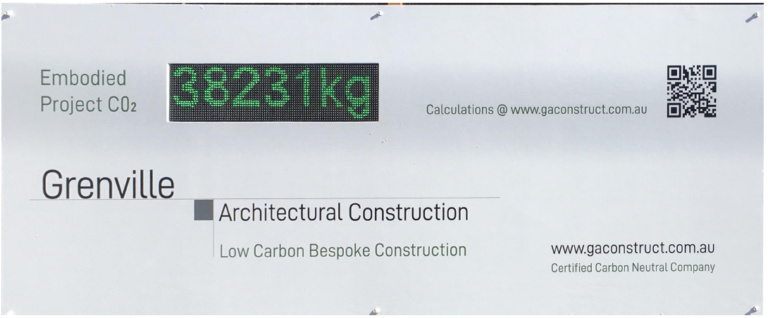

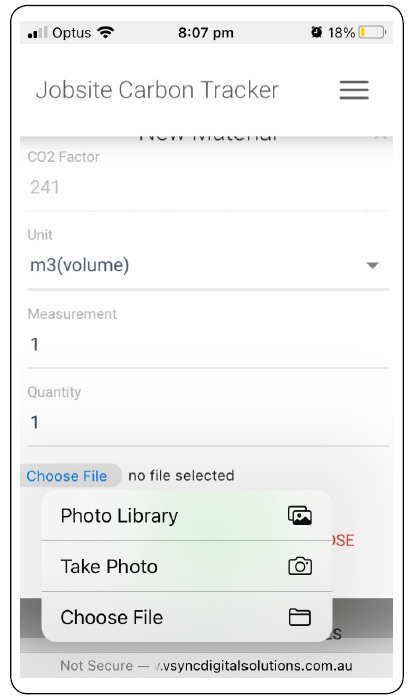

Digital technologies have also been developed for the residential sector. Tom Petty, Founder of Grenville Architectural Construct, recently designed the Carbon Tracker, an application that logs and presents the carbon emissions associated with projects on a digital panel on site. Architects and builders provide data input on materials to Carbon Tracker and are given a carbon estimate for the materials used.

“The real benefit was in these carbon conversations that we had as a result of this digital live sign. The site was down the road from the pub, so we had all types of punters coming in and asking what it was all about.” Says Tom Petty about the first sign they installed on a residential building site.

Just like Mott MacDonald’s Carbon Twin, Carbon Tracker democratises carbon by making it visible and engaging for everyday people walking by the site. It facilitates discussion and awareness of the carbon going into buildings and their materials.

Engineering tools – Material Visualisation and Scheme Design

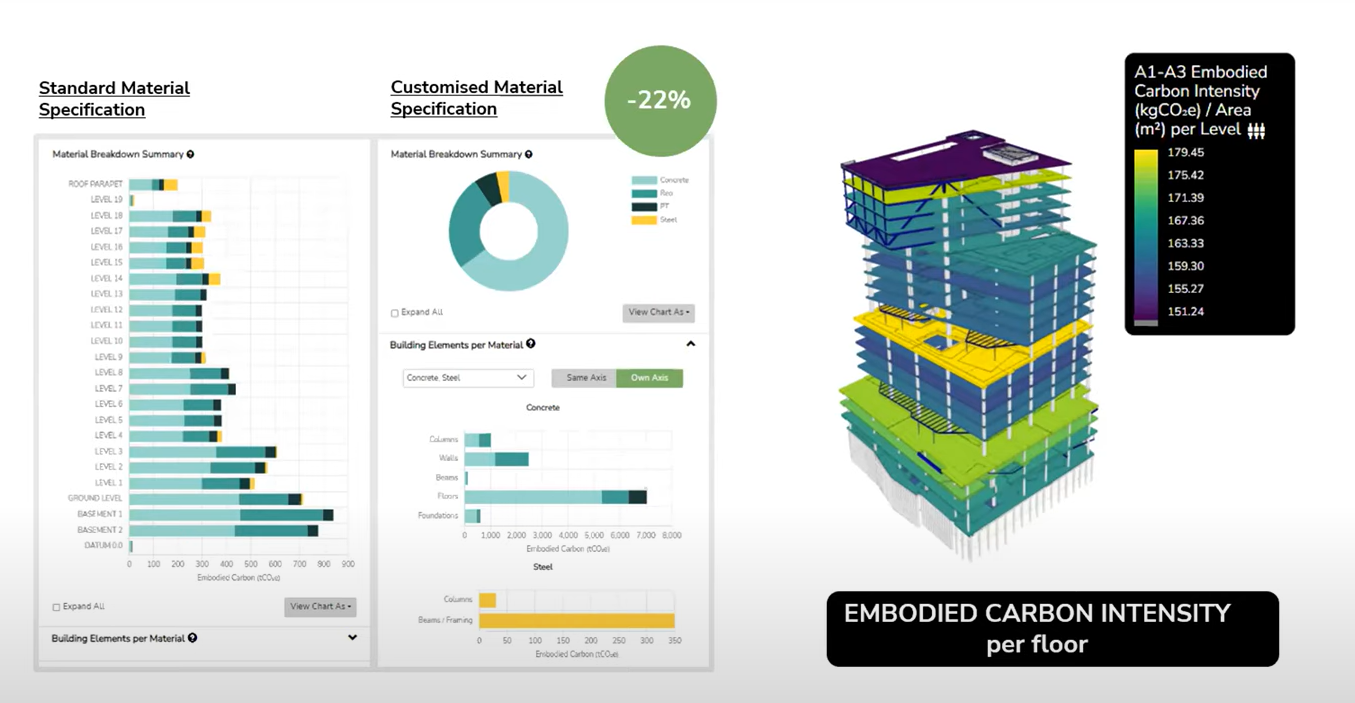

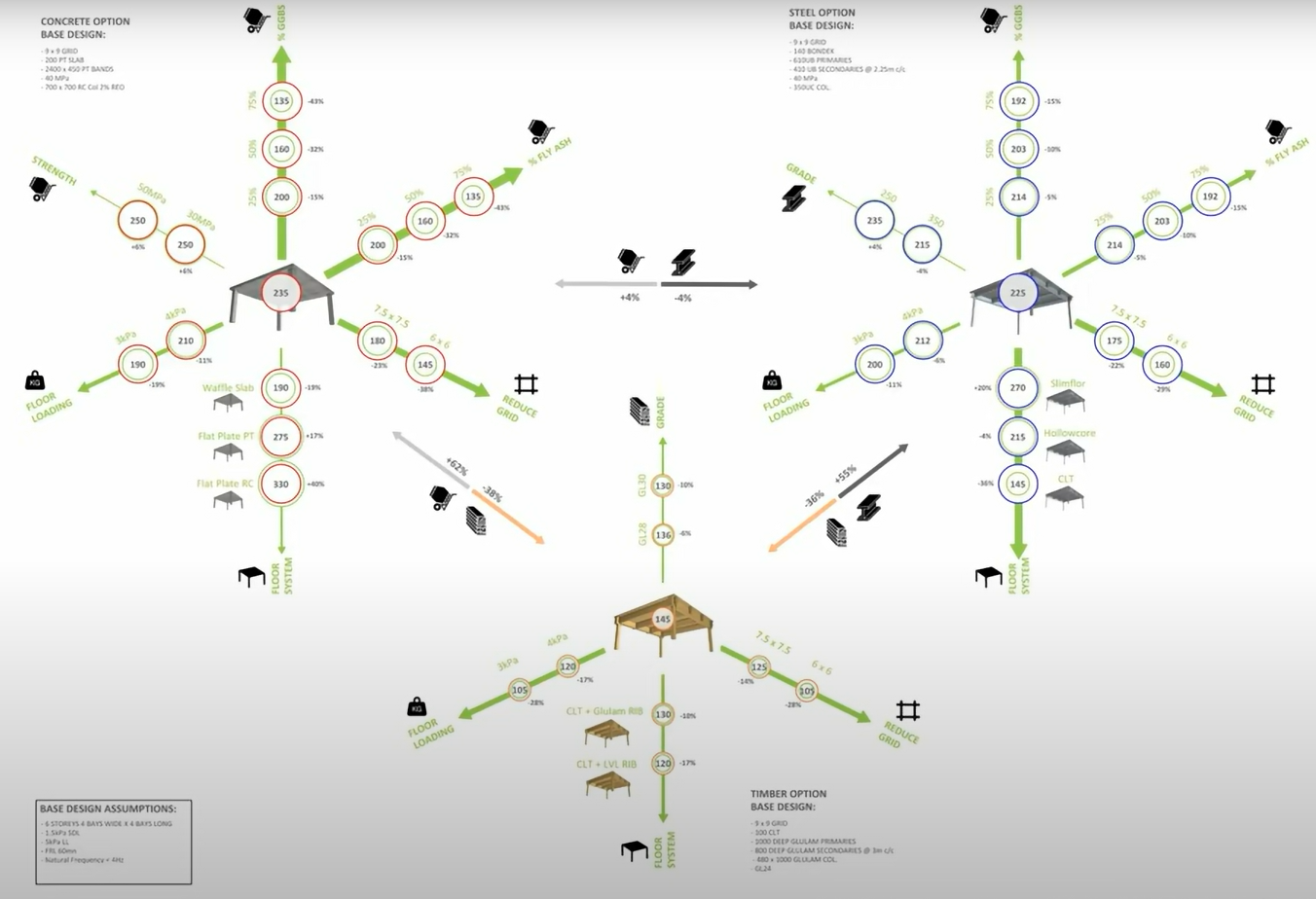

Richa Sud, Senior Sustainability Consultant at Taylor Thomson Whitting (TTW), explored some of the ways TTW mobilises digital engineering to achieve carbon reductions. They created a building information modeling (BIM) based upfront embodied carbon calculator that allows them to facilitate data-driven decision-making, compare and critique designs, and track carbon throughout the design process. The modeling allows TTW to consider carbon as a design parameter. It also becomes an educational tool for understanding why some project outcomes are better than others, as more and more data is stored and analysed through the model.

ARUP also uses BIM to address scheme design and structural components of projects. In their tool, changes to the structural components of the design are compared with the base case and evaluated for carbon savings.

This article originally appeared on the Materials and Embodied Carbon Leaders Alliance Website. To view the original, please click here.